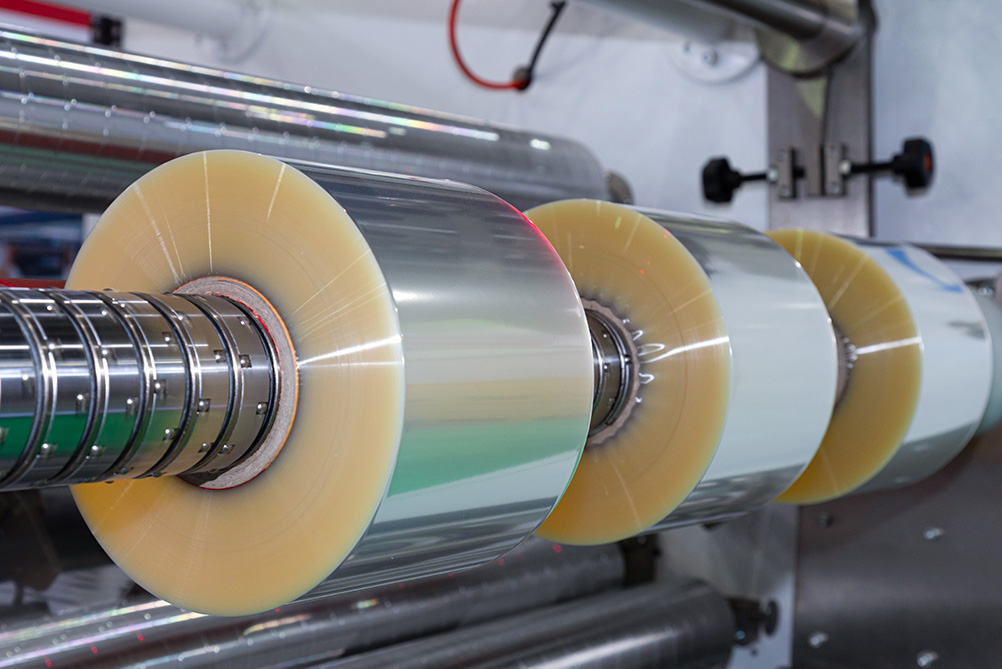

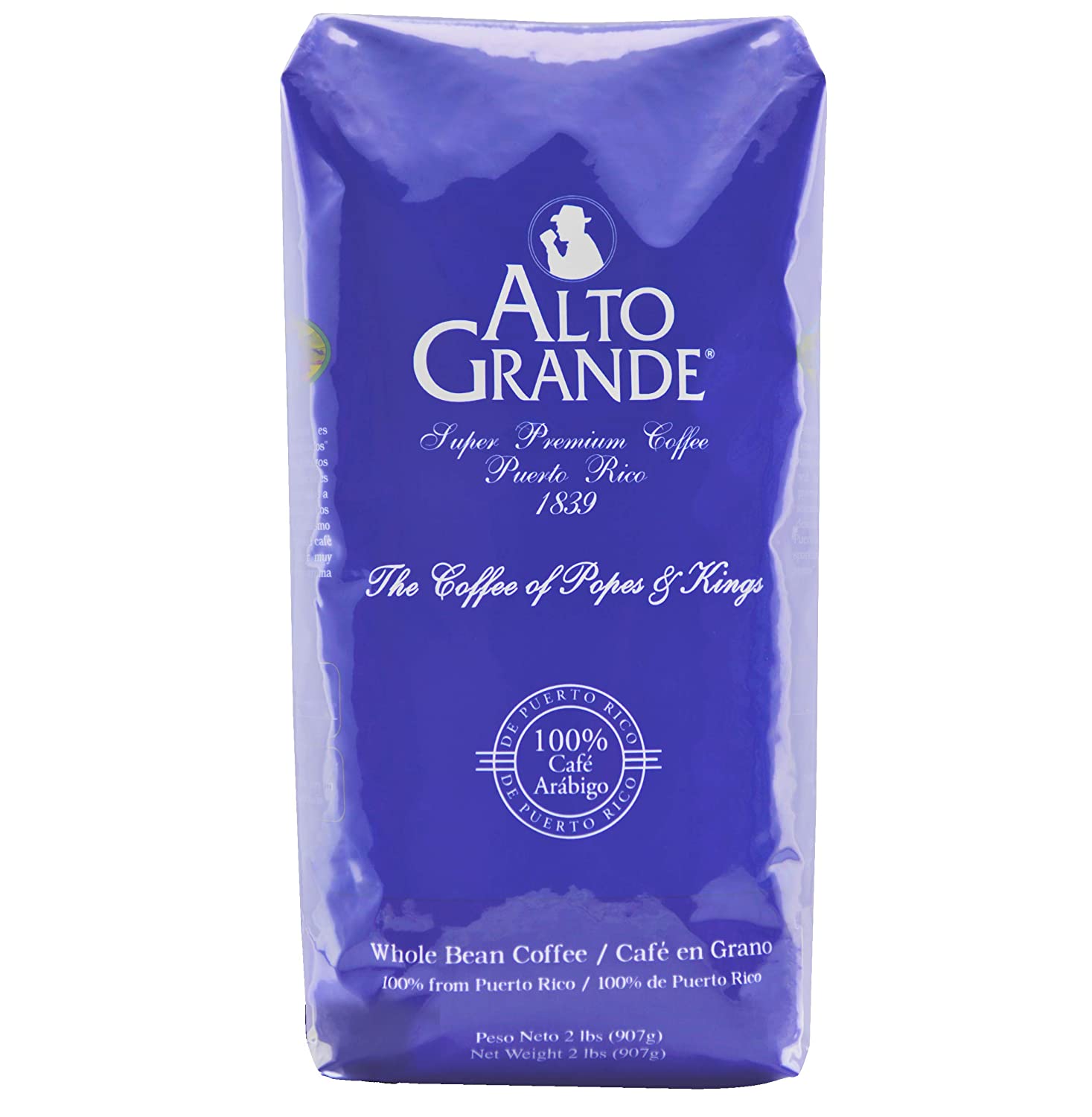

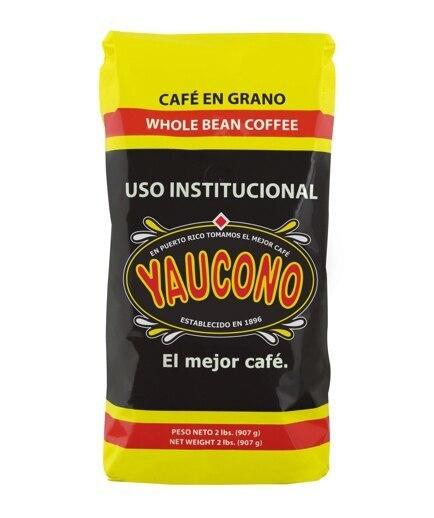

Flexographic

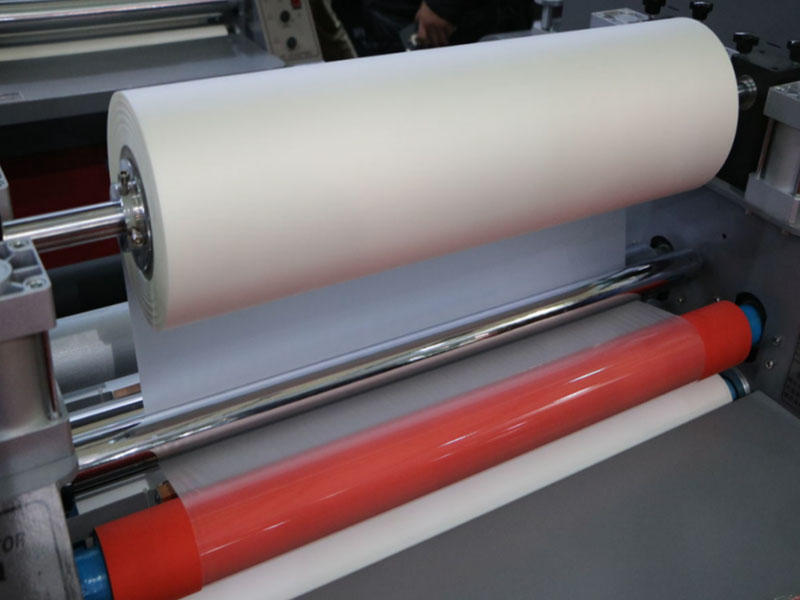

Flexography has been widely used as a quick and economical way of applying simple designs and areas of colour to a wide variety of packaging materials, such as paper and plastic containers (including waxed-paper ones), corrugated-cardboard boxes, tape, envelopes, and metal foil.